|

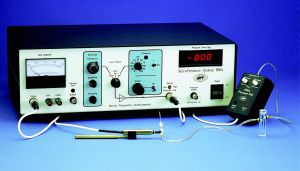

Model 900A is designed to measure hydrostatic pressure in small vessels and cells. Pressure ranges of -200 to +400 mm Hg can be measured with stability and accuracy. The system’s sensing element is an electrolyte-filled glass microelectrode with a tip diameter range of 2 to 5 microns. Pressures of electrolyte solutions are measured by maintaining a salt concentration gradient at the tip of the sensing electrode in dynamic equilibrium by applying an equal air pressure inside the microelectrode. The pressure reading appears on the front panel display and via the BNC recorder output. Because the piezoelectric pressure controller uses external pressure and vacuum sources, pressures lower than -200 to greater than +400 mm Hg can be quickly and accurately measured at the microelectrode tip.

Open pressure chamberThe open pressure chamber is almost immune to vibrations and movements and, unless they are extremely large, the open system is unaffected by leaks. The pressure controller is contained in a small, lightweight enclosure that can easily be mounted near the micropipette to help reduce dead space. It includes an amplifier, a piezoelectric valve and a pressure transducer. The user supplies fluid-filled microelectrodes, +500 mm Hg pressure source and a -300 mm Hg vacuum source.

Electric potentialMeasuring electric potential and pressure simultaneously lets you use potential recording as an additional cue for locating the electrode where visibility is limited, or correlate pressure and potential when this is meaningful. The unique “Set Pressure” mode lets you preset the internal pressure of the microelectrode - select a positive pressure for flushing the tip, or a negative pressure for pulling solution into the tip. By disconnecting the microelectrode holder and attaching the tubing to a manometer, you can check the calibration against a standard.

Built-in alarmA built-in alarm sounds to indicate maximum pressure. The alarm also sounds when the tip is blocked or electrical continuity is broken (e.g., the microelectrode comes out of the solution, too little filling solution to cover the Ag/AgCl pellet, disconnected ground reference, etc.).

Piezoelectric pressure controllerThe piezoelectric pressure controller regulates internal pipette pressure by controlling air flow into and out of a small pressure chamber. A vacuum source is connected on the outlet side of the chamber, and a piezoelectric valve meters air entering the pressurized chamber. The residual volume of the pressure chamber includes the micropipette, the connecting tubing and the pressure transducer on the outlet side of the piezoelectric valve. The 900A accurately controls and adjusts the pressure in the chamber to match pressures applied externally to the microelectrode tip. The response time of the piezoelectric valve is 0.5?ms from fully closed to fully open. Overall system response time depends largely on the amount of residual volume in the tubing. When this volume is small, the system responds very rapidly (typically 10 milliseconds).

Minimize dead spaceThe lightweight pressure controller pod may be mounted close to the microelectrode using small-bore tubing, to minimize system dead space.

NoteMicroelectrode

holders MEH6RF and MEH6SF for 1.0?mm O.D. capillary glass included. (1.2,

1.5 and 2.0?mm also available - please specify when ordering.)