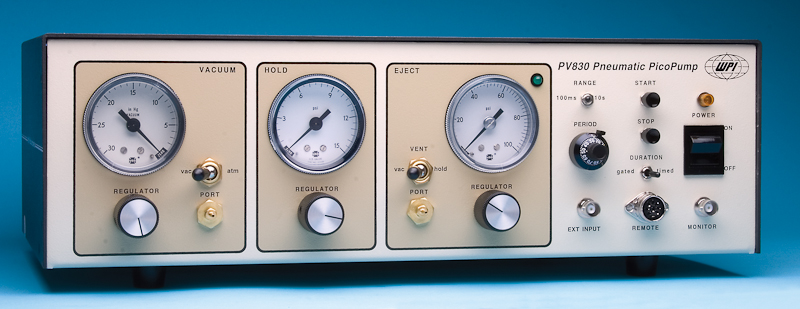

■ PV830 Pneumatic Picopump with vacuum

氣動皮升奈升泵

‧Regulated Hold, Ejection and Vacuum

Pressure

‧Carefully regulated air pressures for securing cells and injecting them

with fluid

‧Pressure Input: 0-150 psi

‧Pressure Output: 0.3-90 psi

Intracellular injection

Designed to simplify intracellular injection and a variety of other microinjection tasks, WPI™s PicoPumps use carefully regulated air pressures for securing cells and injecting them with fluid. Injected volumes range from picoliters to nanoliters. Separate ports supply positive and negative pressure - positive pressure for high-pressure ejection, and suction for supporting the cell or for filling the pipette from the tip. A second pressure port maintains a low positive "holding" pressure to the injecting pipette between injection pulses, to prevent fluid uptake through capillary action or diffusion. Timing, ejection pressure, holding pressure, and suction are adjusted independently by control knobs and indicator gauges on the front panel. Injection pressure is controlled by a 20-turn regulator on the front panel. A built-in timing circuit allows precise control of the amount of time that the injection pressure is applied to the output port. Time intervals can range from 10 seconds down to 10 ms or less, depending on the eject pressure setting. The injection pressure interval can be triggered manually on the front panel, by footswitch, or by computer controlled TTL pulse. A 5 volt monitor output provides a logic-level pulse for your computer or other monitoring device.

PV830 Features

Eject pressure, Hold pressure, and Vacuum are all available, controlled by separate regulators on the front panel. Eject pressure supplies a high-pressure pulse for injecting fluid. Hold pressure, which is not sufficient to cause fluid ejection, is used to prevent back filling of the pipette by capillary action or diffusion when the solenoid is inactive. Pressure in the injection pipette is automatically switched between Eject and Hold pressure by a precision timing circuit that controls a solenoid valve. Vacuum is used to fill pipettes from the tip or to secure a floating cell during microinjection. Vacuum is regulated the same way, by a 20-turn knob on the front panel. Vacuum may be switched from regulated vacuum to atmosphere by using the pneumatic toggle on the front panel. Vacuum can also be routed to the eject port.

OPTIONAL ACCESSORIES

|

3260 |

Foot Switch |

|

2933 |

Rack Mount Kit, 3.5"" high |

|

5430-10 |

PicoNozzle Kit (MPH6S for 1.0mm pipette and 5' tubing assembly) |

|

5430-12 |

PicoNozzle Kit (MPH6S for 1.2mm pipette and 5' tubing assembly) |

|

5430-15 |

PicoNozzle Kit (MPH6S for 1.5mm pipette and 5' tubing assembly) |

|

5430-20 |

PicoNozzle Kit (MPH6S for 2.0mm pipette and 5' tubing assembly) |

|

5430-ALL |

PicoNozzle Kit (for 1.0, 1.2, 1.5 and 1.65mm pepette and 5' tubing assembly) |

|

MPH6S |

Micropipette Holder (specify 1.0, 1.2, 1.5 or 2.0mm) |

|

MPH6R |

Micropipette Holder (specify 1.0, 1.2, 1.5 or 2.0mm) |

|

3316 |

Replacement Input Kit |

Specifications

| PRESSURE | |

| Pressure Input | 0-150PSI |

| Pressure Output | 0.3-90PSI |

| Lowest Regulated Pressure | 12" water |

| Regulator Accuracy | 0.1% (20-turn dial) |

| Regulator Repeatability | 0.05PSI (both hold and eject pressures) |

| Gauge Accuracy | 3% at full scale (both hold and eject pressures) |

| Input Connector | Quick Connect (1/4" OD tubing) |

| Output Connector | Barbed (1/16" ID tubing) |

| Control | Solenid |

| VACUUM | |

| Vacuum Input | 0-30.0" Hg |

| Vacuum Output | 0.2-29.9" Hg |

| Lowest Regulated Vacuum | 3" water |

| Regulator Accuracy | 0.1% (20-turn dial) |

| Regulator Repeatability | 0.03" Hg |

| Guage Accuracy | 3% at full scale |

| Input Connector | Quick Connect (1/4" OD tubing) |

| Output Connector | Barbed (1/16" ID tubing) |

| Control | Manual |

| Vent | Atmosphere |

| CONNECTIONS INCLUDED | |

| Input Kit | 10' nylon tubing (0.25" OD, 1000PSI), one 1/2" female NPT adapter |

| Output Kit | Two PicoNozzle |

| PHYSICAL SPECS | |

| Power | 95-135V or 220-240V, 50/60Hz |

| Dimensions | 17 x5.25 x 9.5" (43 x 13 x 24cm) |

| Shipping Weight | 14 lb. (6.3kg) |